Introduction

Accidents ruin profit and image of process plants and accidents are caused mainly due to mechanical failures or operational errors.

Most of today’s process plants like refineries, gas plants, power plants, fertilizer units and petrochemical plants are large, complex and integrated. The quantum of instrumentation, control logics and interlocks involved in these operations is quite enormous and varies from plant to plant. The various advanced control and optimization techniques that are implemented in many plants automate the critical plant operations and greatly remove routine operator actions. Also the existing plants are being upgraded both technology-wise and capacity-wise to give a boost in their performance.

ProSimulator

Primary benefits:

The ProSimulator™ OTS systems offered are custom developed, high fidelity training systems and will enable the client to provide continuous training and development of operator and engineers. By using the OTS systems, the client will be able to:

➤ Improve operating experience, confidence and accuracy in normal and abnormal

plant operations.

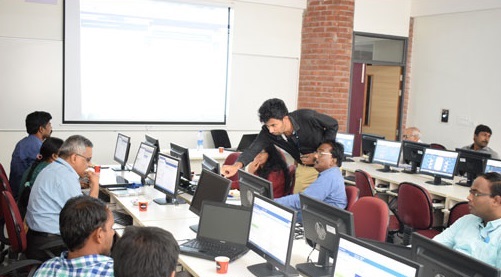

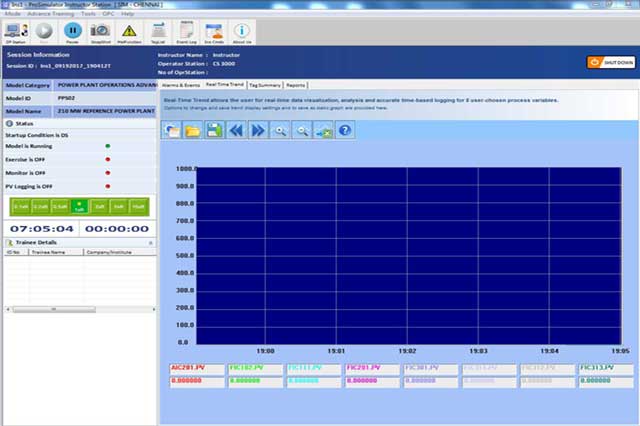

Instructor Station

ProSimulator™ Instructor station enables the instructor to control and direct the training sessions. To improve the ease of instructor actions, a graphical user interface with multiple windows, scroll windows, pull down menus, icons, 3D push buttons and dialog boxes are provided. All the actions can be enabled using a mouse pointer or touch screen. Thus an experienced instructor can work efficiently and a novice instructor can learn fast. The PC Windows XP -based ProSimulator™ instructor station combines the power, compatibility and simplicity with reduced learning time and greatly improves productivity. Thus ProSimulator™ instructor station groups common functions in a primary window, and lets you access other pertinent information through supplemental window. We have incorporated the “look and feel” feature of the industry - standard GUI user interface to make the instructor station more versatile and powerful.

Download

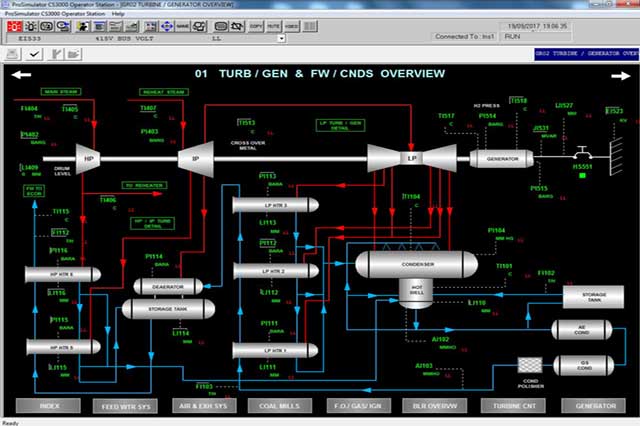

Operator Station

The operator station is the heart of any simulation system. It is the window through which an operator or an engineer monitors, controls and manages the process plant. ProSimulator™ provides emulation for various DCS like Honeywell TDC3000, Yokogawa Centum CS3000, Yokogawa Centum VP, Experion, Fox I/A, Siemens PCS7, DeltaV, ABB Harmony and ABB 800xA . All functions and features that are essential for training are included.

Process Models

Sim Infosystems offers rigorous hi-fidelity dynamic simulation models for Refinery, Fertilizer, Gas processing and Petrochemical process plants. With our rich experience in Industry, we have already developed standard (generic) simulation models for most of the equipments unit operations and industrial plants.

We also offer to develop custom made simulation models for specific process unit, based on plant data. We have rich experience in developing such rigorous custom simulation models for process & power plants.

Training Services

To achieve operational excellence, companies must consistently improve their team’s knowledge, skills and commitment. Employee training is one of the most important investments a Company can make to maximize return on investment.

We are providing operations training programs to refining, fertilizer, gas plants, petrochemical and power industries. Our courses focus on plant operations and provide necessary theoretical inputs as well as simulator based hands-on-experience. The trainees go through normal plant operations, familiarize with plant configuration and control system, malfunctions, start-up, shutdown and emergency shutdown systems.

We have a panel of experienced instructors, who have rich operations experience. The trainee’s performance are monitored and evaluated by these instructors.

Read More