Accelerate performance, enhance safety, and optimize processes with advanced simulation technologies.

Industrial exposure and hands-on training to Engineering / diploma students on virtual plant simulators

20+ years of experience | 100+ Clients | 200+ Projects

From the Instructor station, multiple independent training sessions can be invoked by the Instructor and each training session can be assigned to work with one or more operator stations.

Using this software, the Instructor can load a model, set an initial condition, invoke malfunctions, take/ recall snapshot, change simulation speed and monitor & evaluate the performance of the trainees

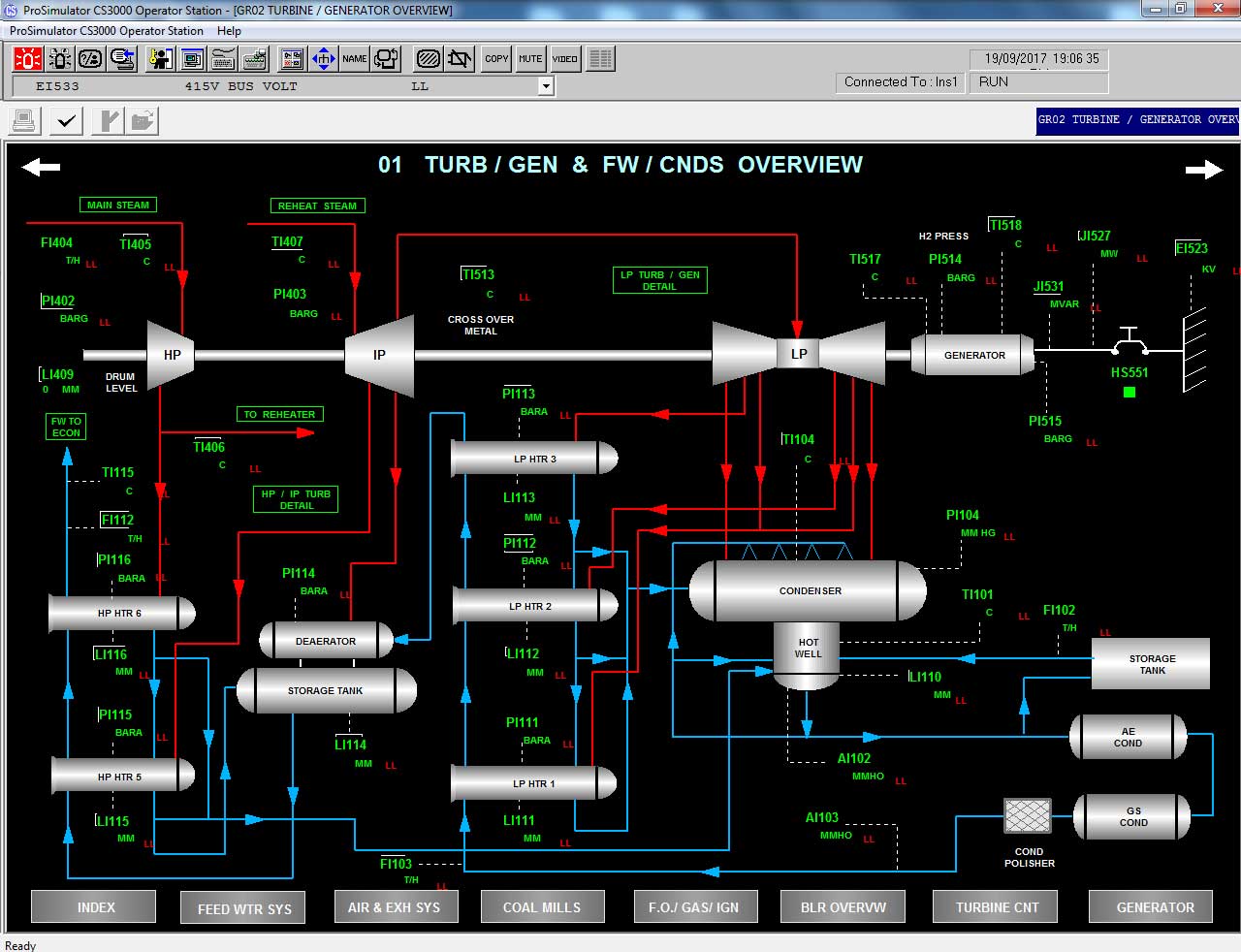

ProSimulator™ provides opportunities to manipulate systems to simulate all possible emergencies and abnormalities, including plant startup and emergency shutdown that an operator has to face, when placed in the actual process plant control room.

ProSimulator™ Instructor station enables the instructor to control and direct the training sessions. To improve the ease of instructor actions, a graphical user interface with multiple windows.

The operator station is the heart of any simulation system. It is the window through which an operator or an engineer monitors, controls and manages the process plant.

Over 200+ projects delivered with measurable benefits in safety, training, and performance optimization. Explore how SIM INFOSYSTEMS has helped clients:

Omega Simulation engages Sim Infosystems services for Tokyo Gas LNG Terminal and TAIKO Bioethanol production OTS Projects.

Installed ProSimulator™ PS2000 packages in Rajalakshmi Engineering College, Chennai.

Installed ProSimulator™ PS1000, PS2000 packages in CSIR-IICT, Hyderabad,Telengana.

Installed All Prosimulator™ models at CIPET,Bhita, Bihar.

Installed ProSimulator™ PS2000, PS5000 packages in Mechanical Department at Kongu Engineering College,Erode.

Installed PS2000 Package at Hindustan College of Engineering and Technology, Coimbatore.

Implemented Prosimulator™ Standard models at Dr.Vishwanath Karad MIT World Peace University, Pune.

Copyright Sim Infosystems @2025. All Rights Reserved

Version : 2025.12.1.0